Delta Gear is unmatched in Technical Depth and its State-of-the-Art Facilities. In fact, we often manufacture gears for our peers, as well as our own OEM customers. We are not afraid to tackle those difficult, complex parts, because we have the technology, engineering resources and the manufacturing know-how to get it done. Our capabilities include:

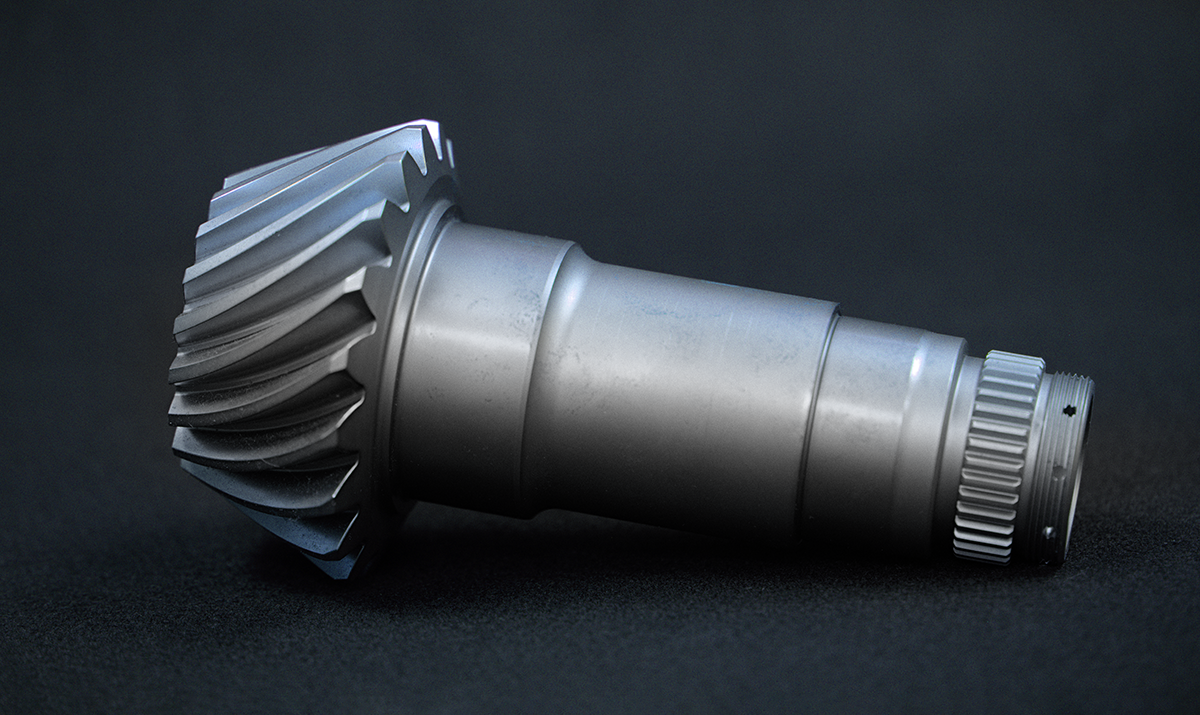

- Spiral Bevel Gears — Hypoid & Zerol

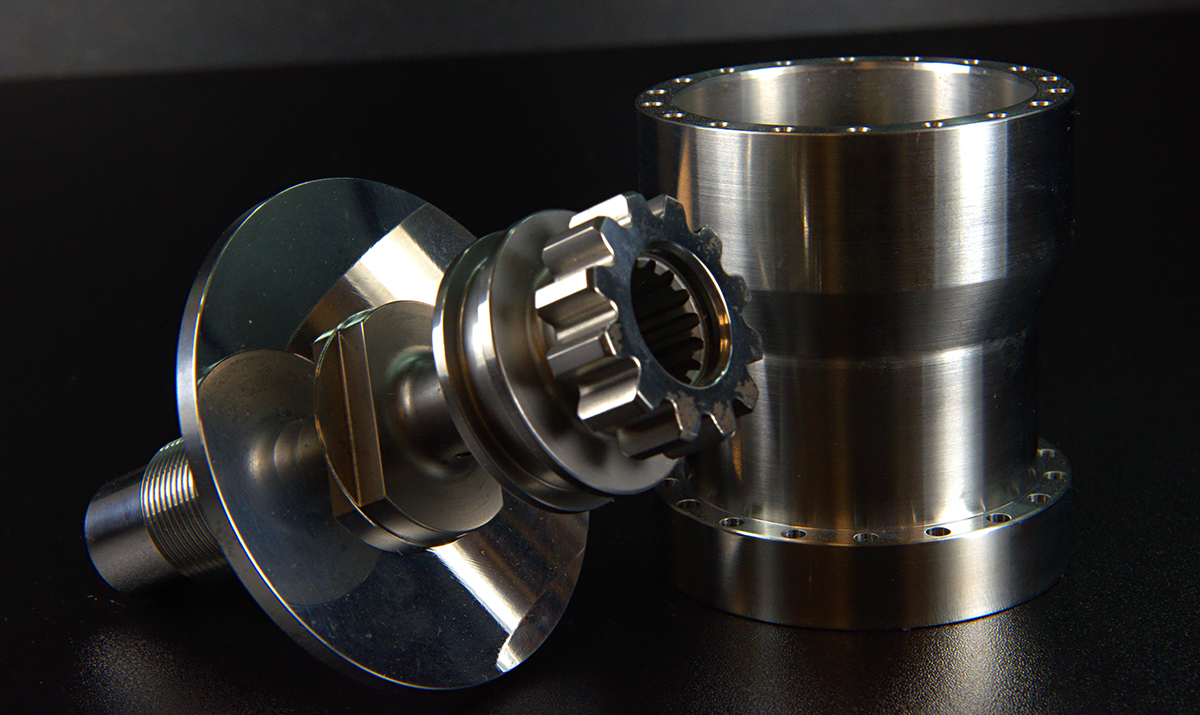

- Curvic Couplings

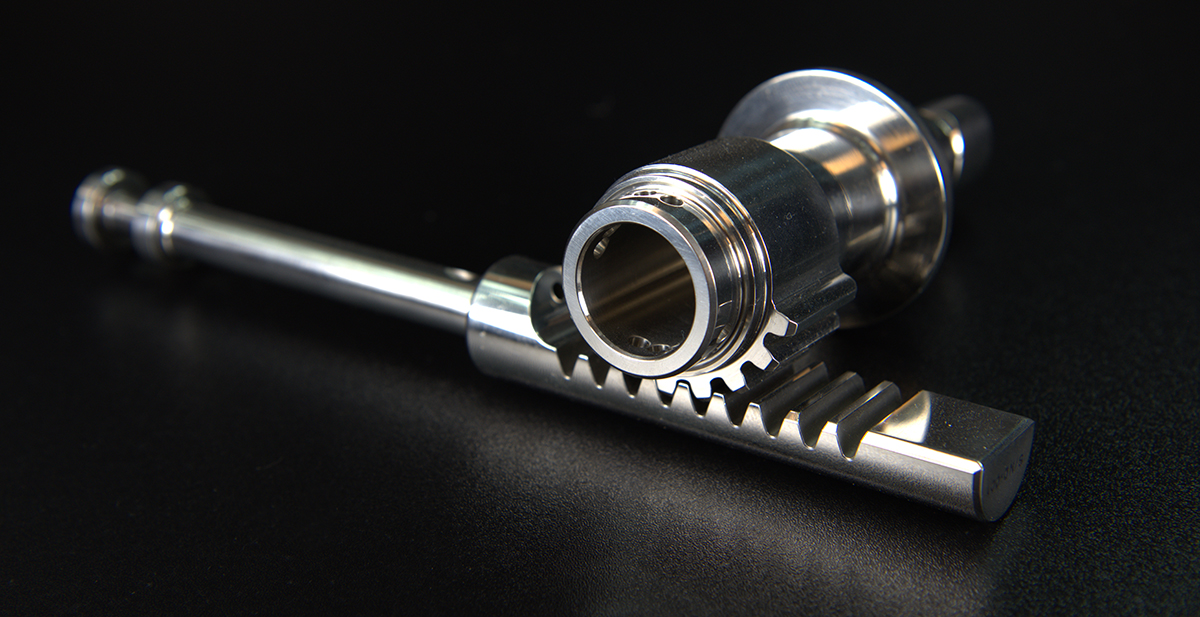

- Internal & External Helical Gears

- Internal & External Spur Gears

- Internal & External Splines

- Crowning & Bias Teeth

- Spherical Teeth

- Precision Prismatic Machining

- Metallurgical Laboratory

- NADCAP Certified

- Nital Etch — A special process to check for surface tempering.

- Magnetic Particle Inspection — A special process to check for material cracking and inclusions.

- Metrology Laboratory

- Non-Destructive Testing

- Gear Tooth Modification

- Gages & Master Gears

- Assembly